Are you also stuck in the DTF vs sublimation dilemma? You’re definitely not alone. It’s like choosing between chocolate and vanilla – both are awesome, but in different ways!

The big 3 differences between DTF and sublimation printing are the materials you can print on, the quality of the print, and how much they’ll cost you.

In this article, I’ll compare sublimation vs DTF so you can choose a printing method that fits your crafting needs perfectly.

Key Differences

Direct-to-Film

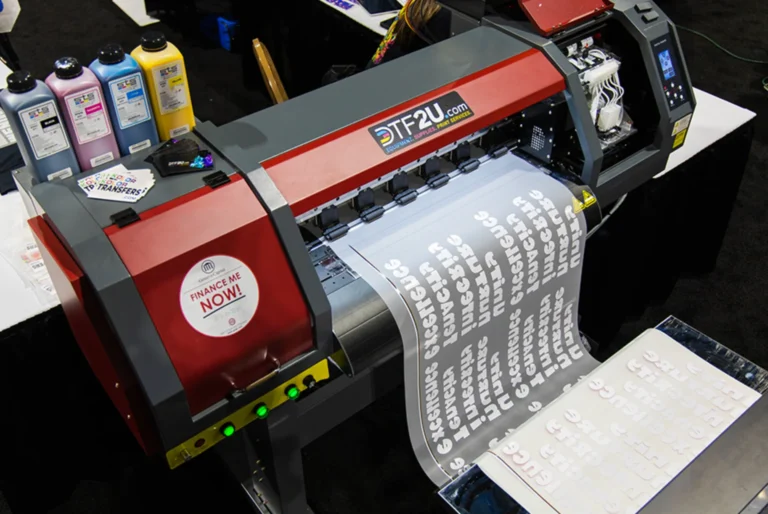

With DTF, your design is first printed onto a film, which is then transferred to the fabric with heat.

This printing method is incredibly versatile. You can print almost on any fabric: cotton, nylon, and even leather. Your designs will also come out more vibrant than from sublimation.

What are the cons? The initial setup is expensive (DTF printers start from $2,000), and they require daily usage and weekly maintenance.

Sublimation

In contrast, sublimation printing uses heat to turn ink into gas, directly dyeing the fabric. Your design becomes a part of the garment, so it won’t crack or fade over time.

However, it’s best suited for polyester and polymer-coated materials. If you’re a fan of natural fibers, sublimation will limit your options.

It’s more budget-friendly, easier to use, and doesn’t require daily maintenance. You can read more about sublimation in my beginner’s guide.

| DTF Printing | Sublimation Printing | |

|---|---|---|

| Application Material | Compatible with various fabrics, including cotton, nylon, and leather. Effective on both dark and light-colored items | Limited to light-colored polyester fabrics or materials with sublimation-ready coating. |

| Print Process | 5 steps: Refinement, printing onto film, curing, heat pressing, and tearing off the film. | 3 steps: Creating design, printing onto special paper, and heat transfer onto the garment. |

| Print Quality | Produces prints with vivid colors and fine details. Allows for a full spectrum of colors, including white. | Offers photo-realistic quality, but colors may be less vivid. Cannot print the color white. |

| Feel on Fabric | The design sits atop the fabric, creating a tactile layer that can be felt. | Sublimation ink merges into the material, creating a smooth feel with no additional layer. |

| Setup Cost | Higher initial setup cost, typically from $4,000 to $15,000. | Lower initial setup cost, typically from $1,000 to $4,000. |

| Skill Level Needed | Involves multiple steps but is generally straightforward. | Fewer steps, and maintenance is way easier. |

Material Compatibility

DTF Printing

DTF is incredibly versatile. It works on a wide range of fabrics, from knits and textiles to unusual ones like Oxford cloth and non-woven fabrics.

Direct-to-film printing is especially good for natural fabrics like cotton, canvas, and linen.

Plus, you can use this technique on both light and dark-colored materials.

Sublimation

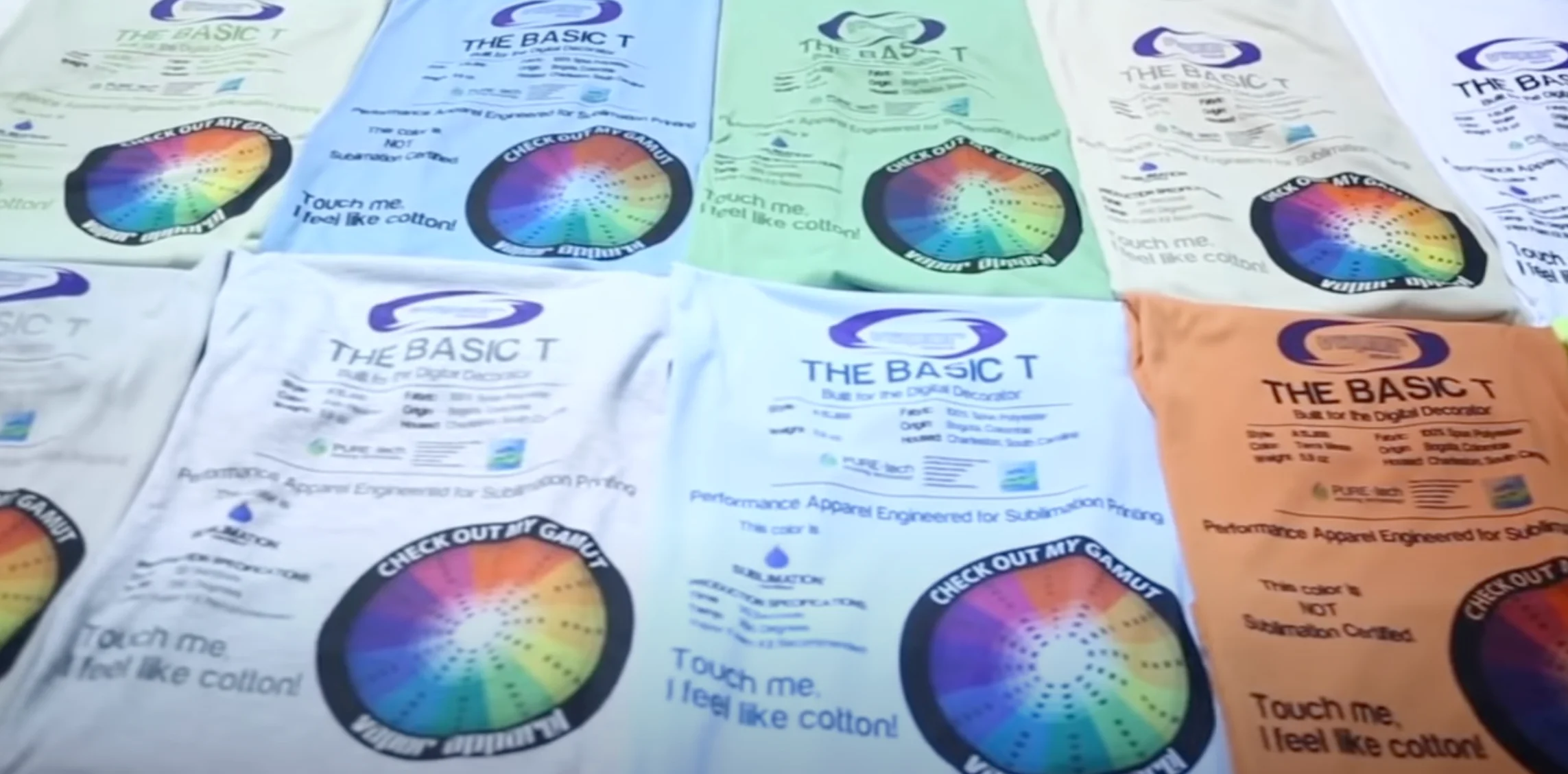

Dye sublimation is more specialized. It mainly works on light-colored or white polyester fabrics. The higher the polyester content, the brighter the colors will be.

While it’s also suitable for other synthetic fabrics like nylon, it’s not great for natural fibers.

Sublimation can also print on hard surfaces if they’re pre-treated with a polymer coating.

Quality and Durability

DTF Printing

DTF gives you vivid colors and fine details. The print sits on top of the fabric, so you can feel it when you touch the material.

Because of this, the print might start to wear after many washes, but it generally holds up well.

Sublimation

Sublimation ink actually becomes part of the fabric. This means you can’t feel it, and it won’t fade or peel.

It’s great for things that will be washed a lot, like sportswear, or items that will be outside, like banners and flags.

Ease of Use

DTF Printing

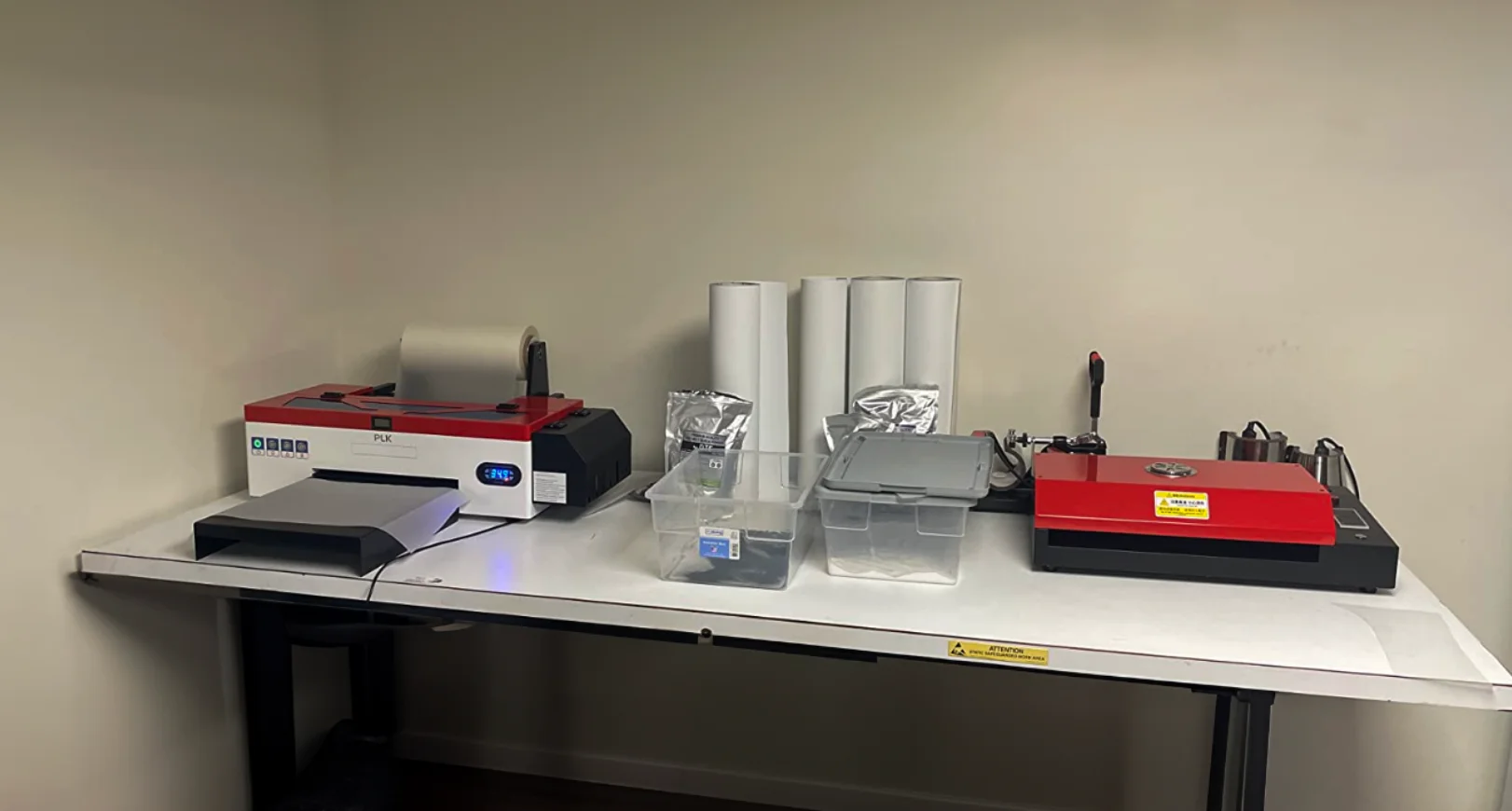

DTF involves a few more steps. You’ll need to refine the design, print it, cure the pattern, use a heat press, and then remove the film.

It might seem like a lot, but once you get the hang of it, it’s pretty straightforward. Plus, most DTF printers have user-friendly software that guides you through the process.

Sublimation

Sublimation is a bit simpler. You design your image, print it, and then transfer it onto your fabric using a heat press. That’s it — just three steps.

Because it has fewer steps, there’s also less room for error, which is a bonus if you’re new to this.

Cost

DTF Printing

DTF printing is more expensive upfront. The printers themselves can cost more (starting from $2000), and you’ll also need to invest in transfer film and specialized ink.

Plus, more steps mean more time spent, which is another kind of expense you should consider.

Sublimation

Sublimation printers are less expensive (starting from $500), and the ink tends to be cheaper.

But remember – you have limited suitable types of material you can print on, which could be a hidden cost if you need to buy special fabric or coatings.

Which is Right for You?

Ultimately, the “right” method depends on what you value most: versatility and range or simplicity and cost-effectiveness.

If you’re into crafting and want the freedom to print on a wide range of materials — DTF could be your best bet. It’s versatile, offers vivid colors, and allows you to feel the print on the fabric.

However, it might cost you more both in terms of money and time.

On the other hand, if you’re looking for something quick and simple, especially for sportswear or polyester-based projects, then sublimation printing is a better choice.

It’s more budget-friendly, easier to use, and offers durable prints that become part of the fabric.